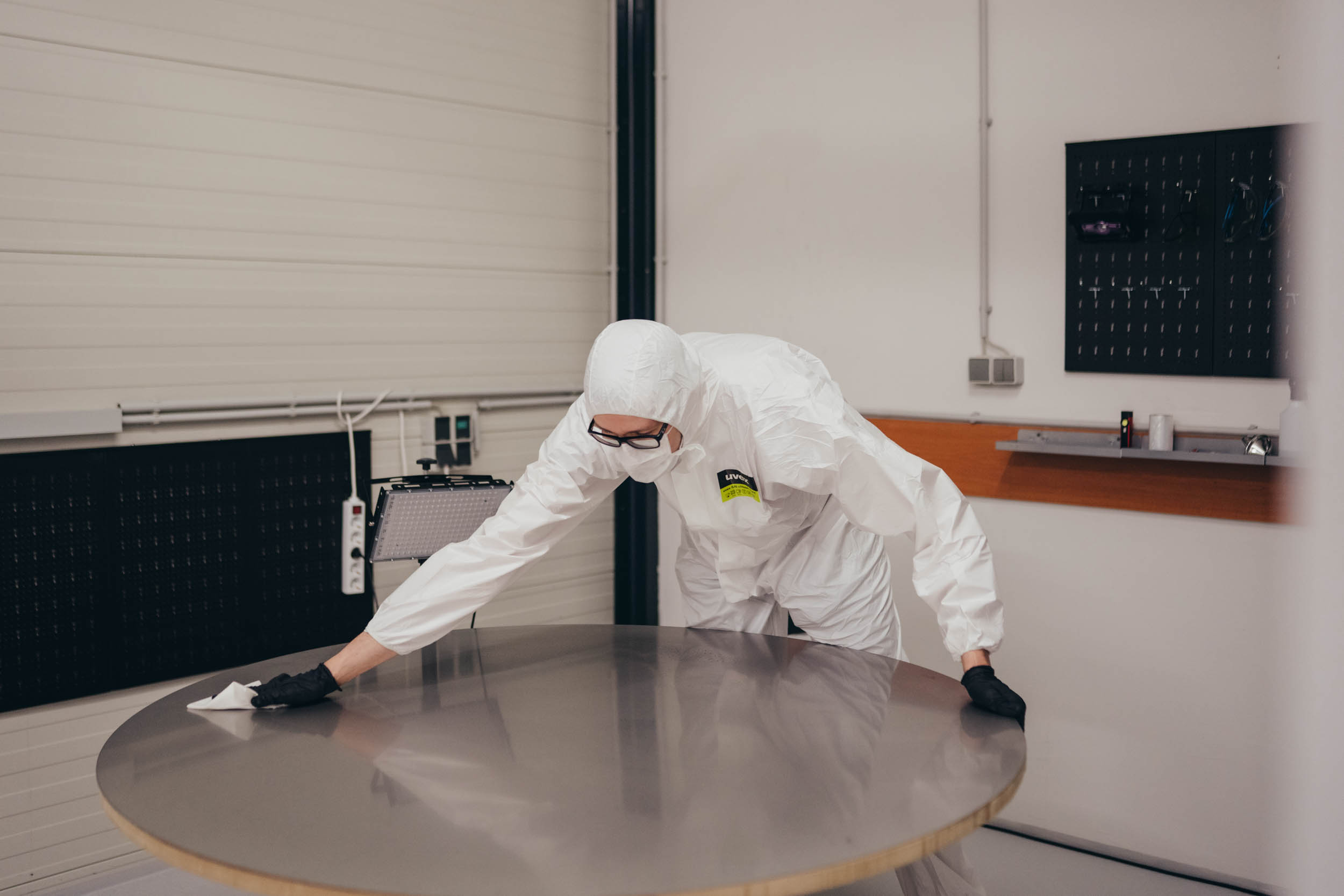

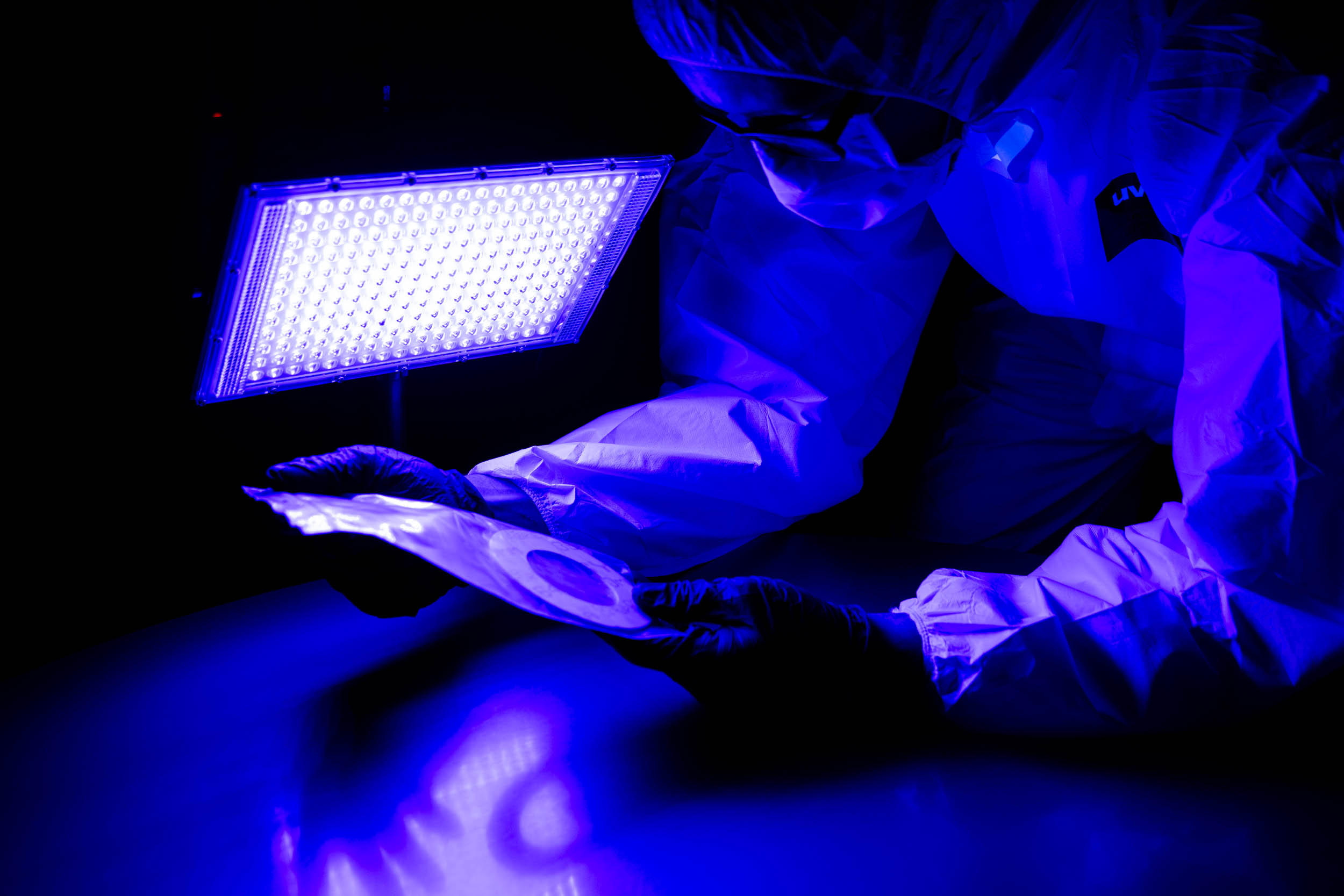

Technical cleaning

Technical cleaning by Sauberraum

In the manufacture of gaskets, the smallest impurities are often caused by abrasion during the manufacturing process, as well as by air and environmental influences. However, where specific requirements are placed on the end product, a high level of cleanliness is crucial to product quality. Even the smallest impurities can cause damage to the products and lead to a high level of rejects. Cleanrooms are used to reduce this risk as much as possible.

A cleanroom is a controlled production environment in which contamination is avoided and cleanliness is monitored. The purpose of cleanrooms is to protect sensitive components and parts in industrial production from loss of quality due to dust and dirt. We have also installed a cleanroom and developed a process for achieving and maintaining technical cleanliness in order to protect your sensitive work areas from critical particle contamination in sensitive areas.

When setting up the cleanroom and carrying out technical cleaning, we followed the “VDA 19.2 – Technical cleanliness in assembly” guidelines, which were published by the German Association of the Automotive Industry in 2010. In accordance with this guideline, we fulfill the classification of cleanliness level 2 and can therefore offer you cleaning services or even an “Oxygen Service” for oxygen-specific applications.

Do you have any questions?

Ready for a solution that lasts?

Contact us today and let us work together to find the perfect solution for your requirements. Do you have a special request? We are ready!