What is pTFE?

PTFE (polytetrafluoroethylene, commonly known under the brand name Teflon® from DuPont) is known for its outstanding chemical resistance, which allows it to come into contact with a variety of aggressive chemicals without losing its physical properties.

PTFE also has a high temperature resistance, which ranges from -200 °C to +260 °C. These properties make PTFE ideal for applications in the chemical, food processing and pharmaceutical industries.

PTFE sleeves

We manufacture PTFE sleeves in both square and round cross-sections, with turned outer diameters of up to Ø 1450 mm possible. Above this dimension and for oval seals, we produce our PTFE sleeves in a welded design by hand.

To increase the diffusion tightness of PTFE, we can also provide the sleeves with a diffusion barrier on the inside diameter.

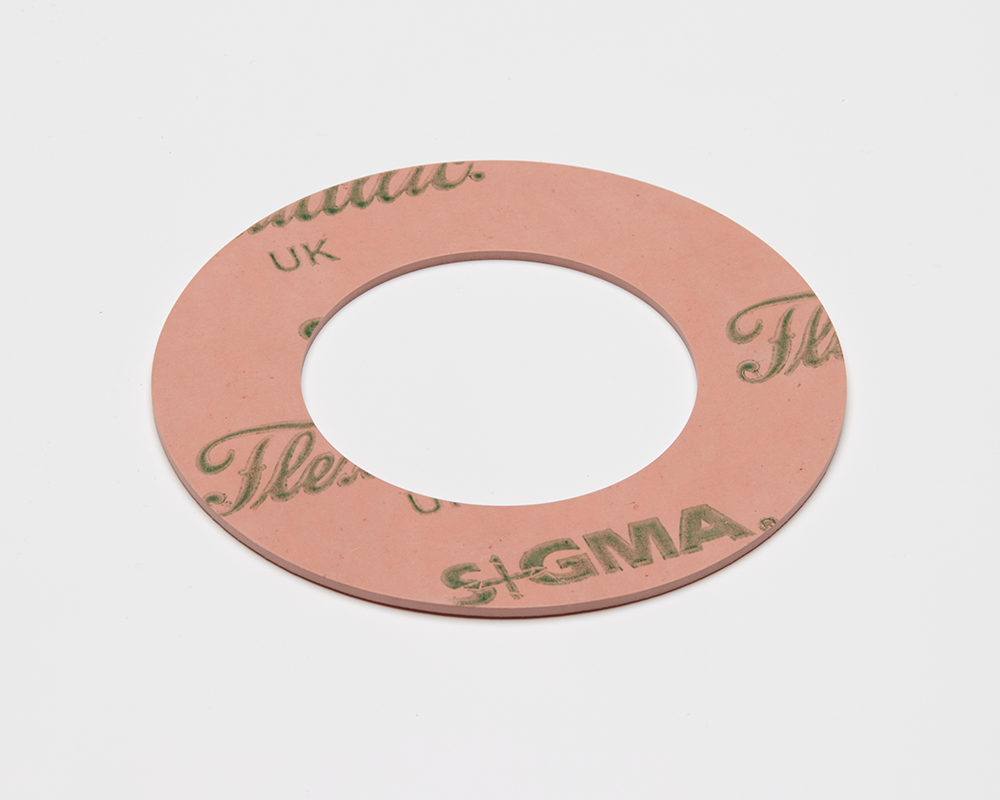

PTFE envelope gaskets

PTFE envelope gaskets consist of a flat gasket at the core, which takes over the mechanical properties of the gasket, and an outer PTFE envelope, whose task is to protect the gasket from chemical attack.

A PTFE envelope gasket is a combination of the advantages of the excellent chemical resistance of a PTFE envelope and the different mechanical strengths of the soft material inserts, such as a fiber, graphite or elastomer gasket. As a result, the advantages of increased pressure resistance compared to pure PTFE flat gaskets are utilized for corresponding applications.

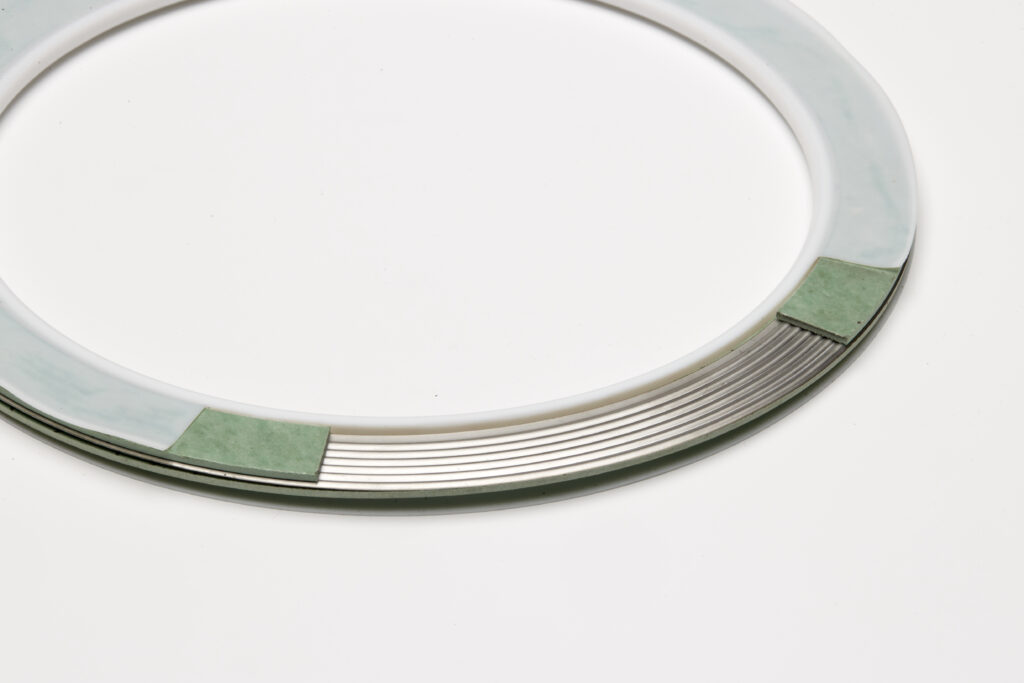

PTFE envelope gaskets with corrugated ring and inserts

The PTFE envelope seal with metallic corrugated ring and soft material inserts is a highly developed sealing solution that combines the respective advantages of three different components in one sealing system. The PTFE envelope protects against the effects of the medium thanks to its excellent chemical resistance, while the corrugated ring ensures the mechanical stability and increased surface pressure of the sealing system.

The soft material inserts, such as aramid fiber, graphite or elastomer, additionally increase the adaptability and pressure resistance of the envelope seal.

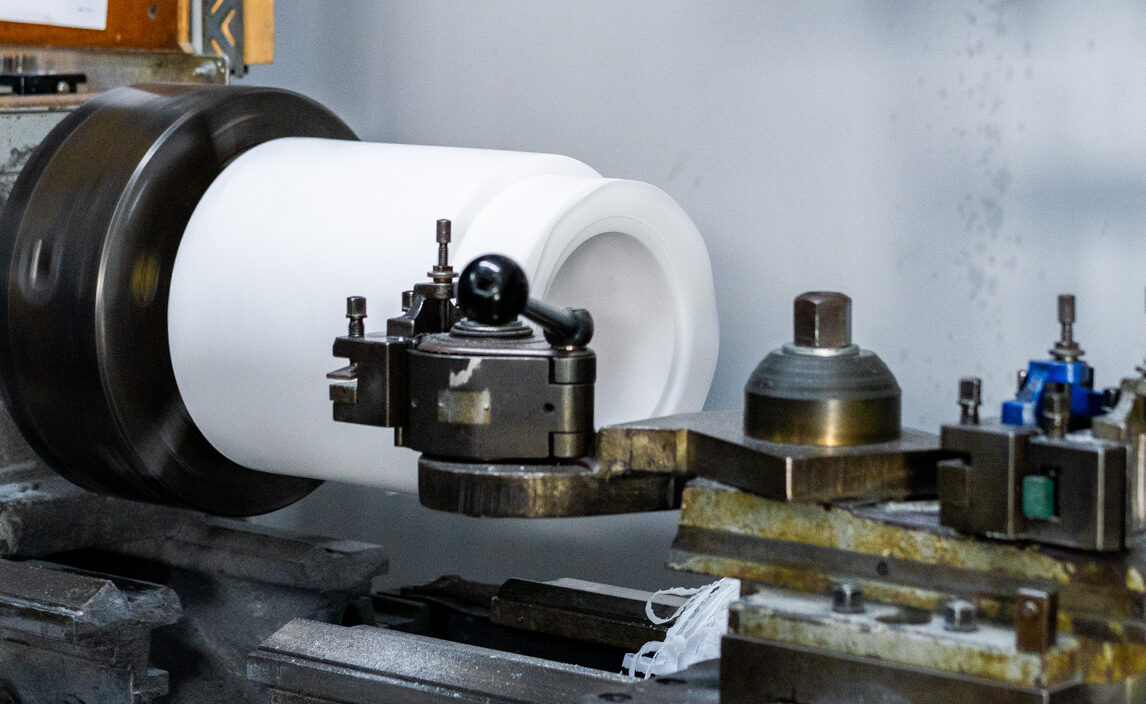

We produce our turned parts from PTFE using our machinery on various lathes. During turning, the material can become thermoformed and therefore requires special and sharp processing tools for the production process. In order to avoid overheating during machining and to guarantee the required surface quality, precise control of the cutting speeds is particularly important.

Other PTFE turned products

Thanks to our many years of experience in the processing of PTFE, we can also produce support rings, O-rings, grooved rings and many other turned parts in addition to sleeves.