Production methods

Production at the highest level

At Becker Dichtungstechnik, everything revolves around precision, flexibility and speed. Our machinery and our experienced employees are ready to meet your individual requirements. From punching standardized gasket dimensions to water jet cutting of complex flat gaskets and sophisticated craftsmanship: We offer comprehensive solutions of the highest quality!

Punching

Our punching processes are optimally adapted to different gasket materials. Thanks to cart beam, bridge and swivel arm punching, we produce precise gaskets for small and medium-sized series. With a tool inventory of well over 4,000 different dimensions in accordance with DIN and ASME standards as well as other common dimensions, we are equipped for any challenge.

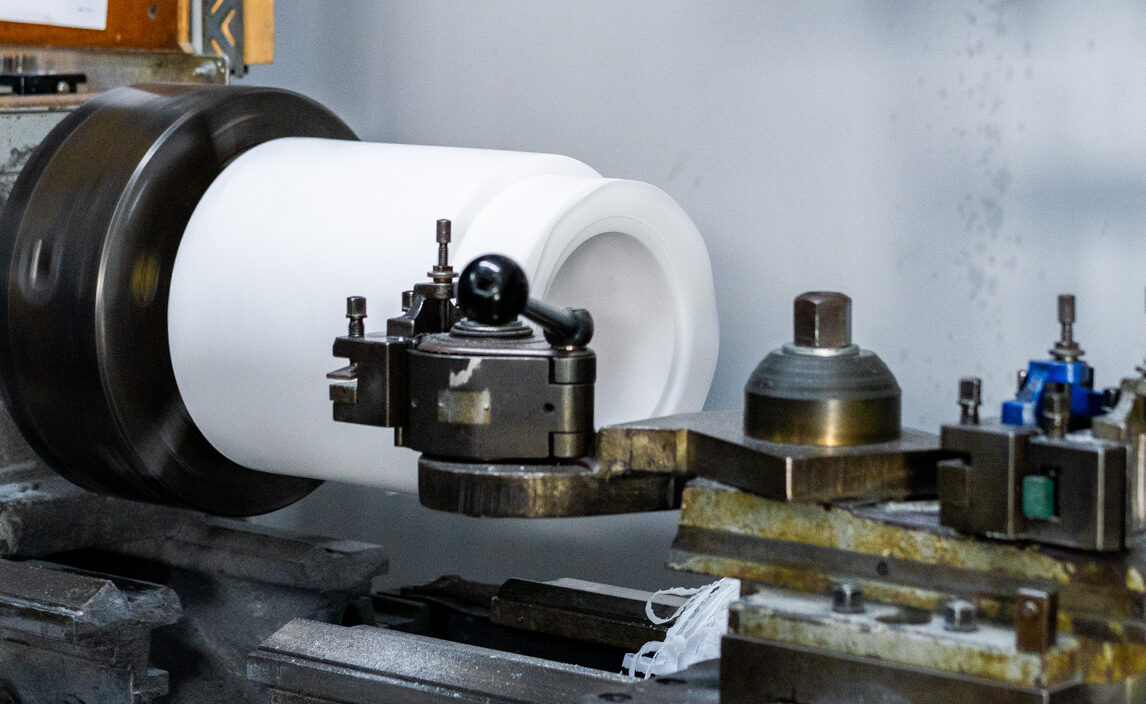

Turning

Our turning technology enables us to precisely manufacture PTFE turned parts up to a diameter of 1,450 mm. Whether a single piece or a series – we achieve the finest contours and highest dimensional accuracy with the help of our machinery on various lathes. This enables us to meet your quality requirements for high-quality turned parts.

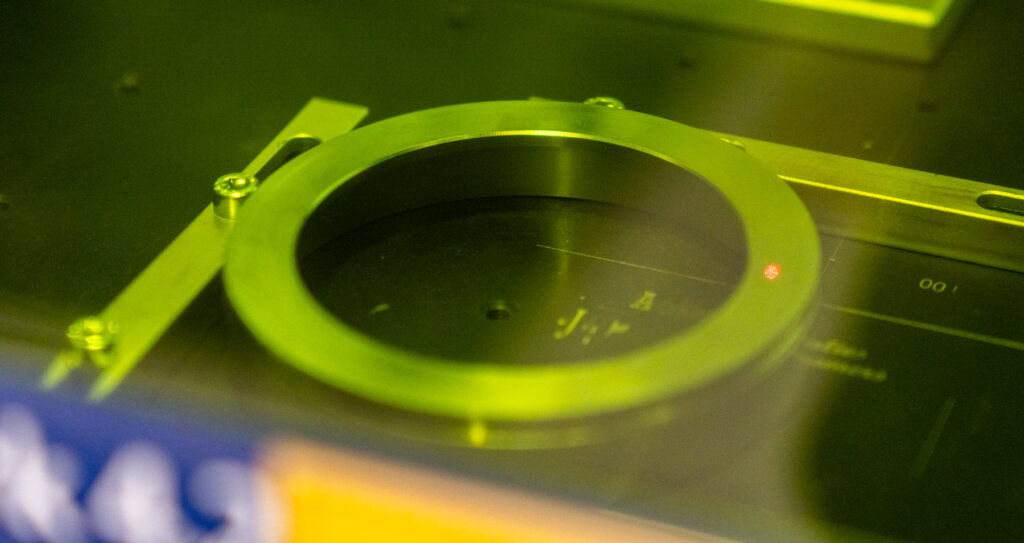

Plotting

For gaskets outside our standard range, as well as for one-off production or complex geometries, we rely on our versatile plotters. This gives us maximum flexibility, speed and cost-effective production of tool-independent gaskets – always in coordination with our technical drawing office.

Water jet cutting

We use waterjet cutting to create intricate cutting patterns, tight radii and large cross-sections – even with very hard materials. For particularly demanding tasks, we use abrasive cutting with quartz sand to precisely meet even the most extreme requirements.

Handwork

Craftsmanship with expertise: For more than 35 years, we have also been able to refine our craftsmanship. This has enabled us to develop our craftsmanship know-how in PTFE welding of segments, shafts and bonding, doubling as well as flanging, grinding, finishing and refining our sealing solutions.

Do you have any questions?

Ready for a solution that lasts?

Contact us today and let us work together to find the perfect solution for your requirements. Do you have a special request? We are ready!